Safety integrity level (SIL)

Safety instrumented system (SIS), also known as instrument safety related system or instrument system performing safety functions, has been widely used in petroleum, natural gas and chemical industries, such as safety interlock system of system unit, PLC emergency shutdown system, fire alarm system, etc. The failure of these systems will lead to huge losses of safety, environment and property. Safety integrity level (SIL) is the requirement for the safety integrity of safety instrument system, which is expressed in discrete data.

►

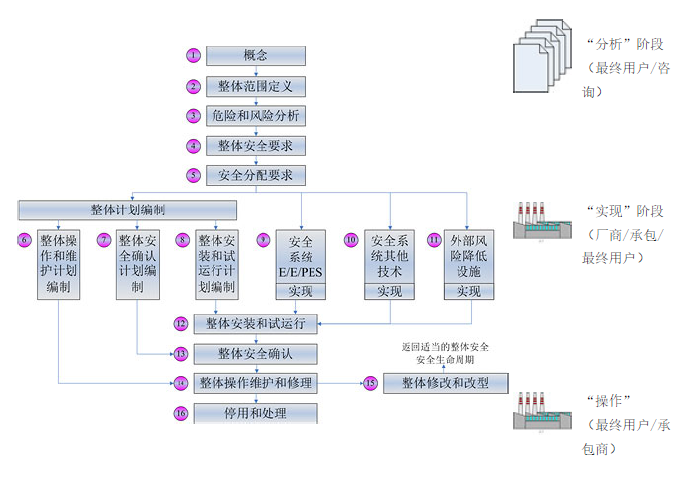

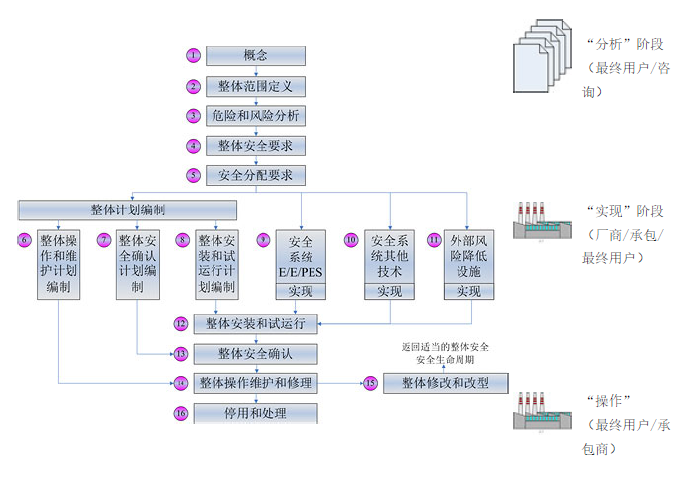

In May, 2000, the International Electrotechnical Commission officially issued IEC61508 standard, entitled "functional safety of electrical / electronic / programmable electronic safety systems". The following figure is the safety life cycle diagram defined in the standard. The selection of SIL is based on the fourth step of the first three steps, which is mainly to determine the protection scope, that is, to determine the scope of EUC; Find out the hazard source; Assess the risk of hazard sources; And determine the allowable risks of hazard sources. The fourth step is to determine the safety function and the safety integrity level of the safety function, namely SIL. The fifth step is to assign safety functions to specific safety related systems, and assign safety integrity levels to each safety related system, that is, to determine the SIL of each safety related system.

IEC 61508 - overall safety life cycle

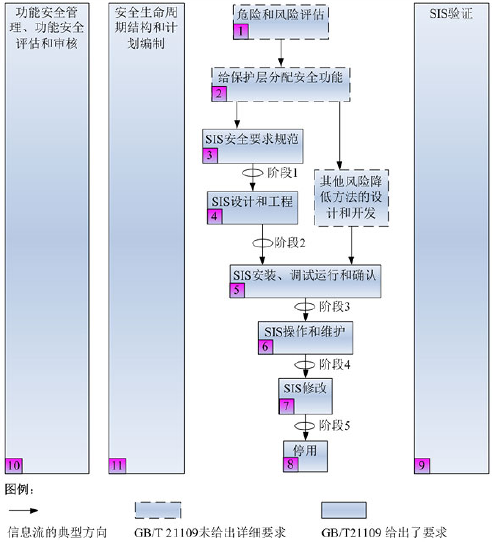

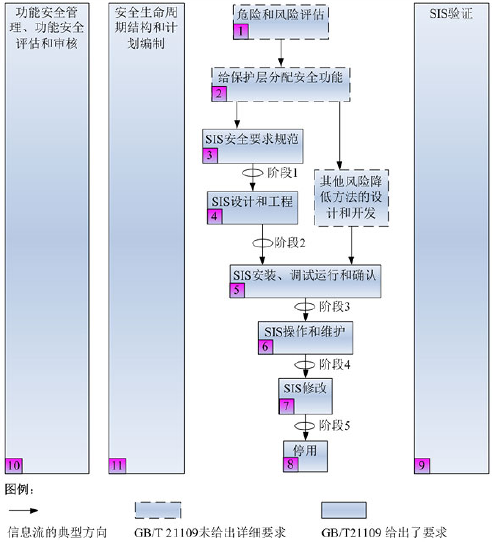

IEC61511 "functional safety of safety instrumented systems in the field of engineering industry" was introduced by the International Electrotechnical Commission after the basic standard of functional safety IEC61508. For the instrument safety system based on the use of electrical / electronic / programmable electronic (e/e/pe) technology, IEC61511 standard stipulates the basic principles that must be adopted in the design and use of logic solvers, as well as the minimum standards that the sensors and final components constituting the instrument safety system should meet, and puts forward the methods of safety life cycle activities to meet these minimum standards, that is, the specification of safety instrument systems in process industry The requirements for design, installation, operation and maintenance have been standardized; Put forward requirements for the system, hardware and software of the safety instrument system. The following figure shows the SIS safety life cycle stage and functional safety assessment stage specified in the standard.

IEC 61511 - safety life cycle phase and functional safety assessment phase

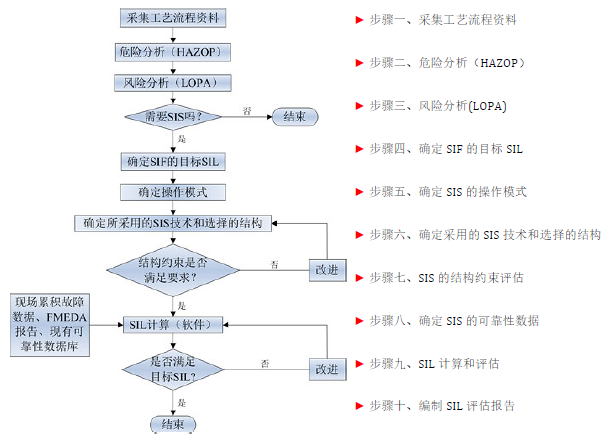

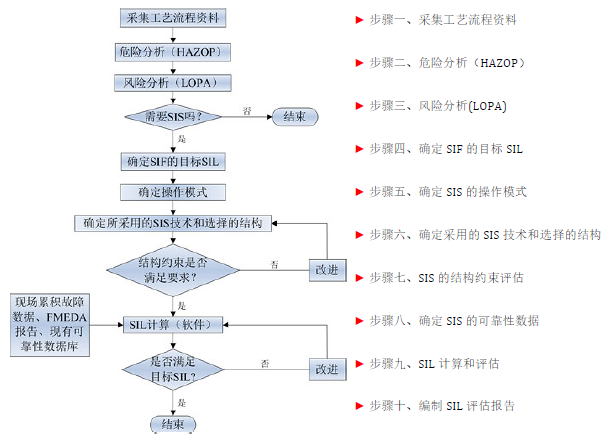

► The SIL evaluation team implements SIL evaluation in strict accordance with the safety life cycle stages specified in IEC61508 and IEC61511 standards. The basic process is as follows: