The degree of protection of the enclosure (IP code) is an important indicator of the safety protection of electrical equipment. The so-called IP code indicates the degree of protection of the enclosure against human access to dangerous parts, the entry of solid foreign matter and water, and the code system of additional information related to these protections. The shell protection grades of the following contents of the specified electrical equipment are: 1) prevent human body from approaching the dangerous parts in the shell; 2) Prevent solid foreign matters from entering the equipment in the shell; 3) Prevent harmful effects on equipment due to water entering the shell. At present, the general standard that meets the requirements of IP protection level is iec/en 60529, and its translated Chinese national standard is GB 4208.

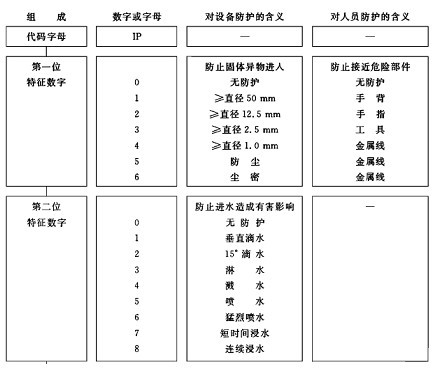

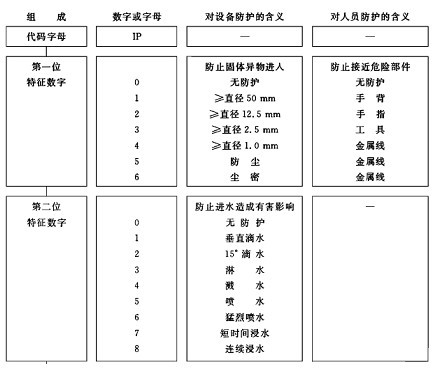

The brief description of each number of IP code is shown in the following figure:

The laboratory is equipped with complete equipment systems such as sand dust test box and rain test box, which can detect dust-proof and water-proof items in accordance with iec/en 60529, GB 4208 and other standards. In order to make our customers understand the test methods and technical indicators, we will briefly introduce them.

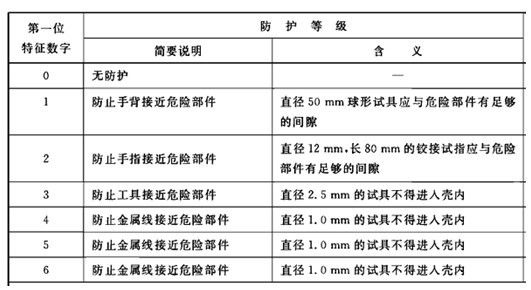

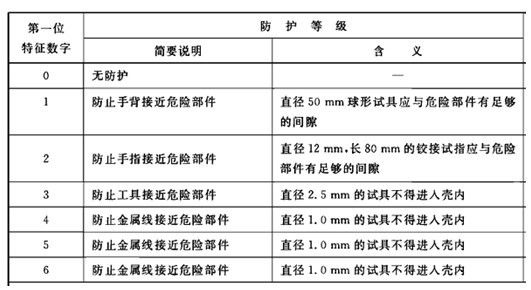

The first characteristic number in the IP code indicates the protection against approaching dangerous parts and the entry of solid foreign matters. The protection requirements for approaching dangerous parts are described in the following table:

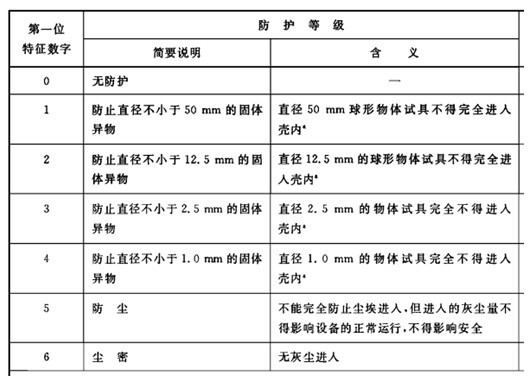

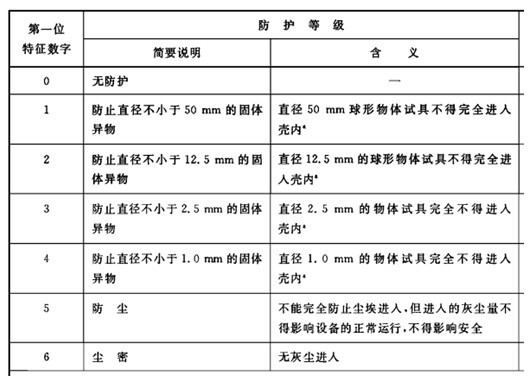

The protection requirements of the first characteristic number in the IP code to prevent the entry of solid foreign matters are as follows:

The second characteristic number in the IP code indicates that the protection level requirements of the shell to prevent the harmful impact on the equipment caused by water entry are as follows (the test is carried out with clean water).

In addition, when the level of preventing the human body from approaching the dangerous parts in the shell is higher than the level indicated by the first characteristic number, the extended range will be expressed by adding an annex letter after the first two digits, which also needs to meet the respective requirements of these additional letters.

The following are the test methods and judgment basis:

IP1 x

Protect solid foreign body detectors with 50mm diameter and larger. The sphere diameter is 50mm and should not be completely entered

IP2 x

Protect solid foreign body detectors with a diameter of 12.5mm and larger. The sphere diameter is 12.5mm and should not be completely entered

IP3 x

Protect solid foreign body detectors with a diameter of 2.5mm and larger. The sphere diameter is 2.5mm and should not be completely entered

IP4 x

Protect solid foreign body detectors with a diameter of 1.0mm and larger. The sphere diameter is 1.0mm and should not be completely entered

IP5 x

Dust protection cannot completely prevent dust from entering, but the amount of dust entering will not cause damage to the equipment

IP6 x

Dust should not enter the dust enclosure at a low pressure of 20 mbar

Waterproof grade (the second X indicates)

(1)IPx 1

Method name: vertical dripping test

Test equipment: dripping test device

Sample placement: place the sample on the rotating sample table at 1r/min according to the normal working position of the sample, and the distance from the top of the sample to the drip hole shall not be greater than 200mm

Test conditions: the amount of dripping water is 10. 5 mm/min

Duration: 10 min

(2)IPx 2

Method name: 15 ° inclined dripping test

Test equipment: dripping test device

Sample placement: make one surface of the sample form an angle of 15 ° with the vertical line, and the distance from the top of the sample to the drip hole is not more than 200mm. After each test, change another face, four times in total.

Test conditions: the amount of dripping water is 30. 5 mm/min

Duration: 4 × 2。 5 min (10 min in total)

(3)IPx 3

Method name: drenching test

Test method:

a。 Swing tube water spray test

Test equipment: pendulum tube type water spray test device

Sample placement: select a pendulum tube with appropriate radius, so that the height of the sample table is at the position of the diameter of the pendulum tube, and place the sample on the sample table, so that the distance from its top to the sample spray port is not more than 200mm, and the sample table does not rotate.

Test conditions: the water flow is calculated according to the number of spray holes of the swing pipe, and each hole is 0. 07 l/min, when spraying water, the water spray from the water spray hole in the 60 ° arc section on both sides of the midpoint of the pendulum is sprayed on the sample. Place the sample at the semicircle center of the pendulum tube. The pendulum tube swings 60 ° on both sides of the vertical line, a total of 120 °. Each swing (2 × 120 °) about 4

Test time: continuous watering for 10 minutes

b。 Sprinkler spray test

Test equipment: hand-held water splashing test device

Sample placement: make the parallel distance from the top of the test to the spray port of the hand-held sprinkler between 300mm and 500mm

Test conditions: baffle with balance weight shall be installed during the test, and the water flow shall be 10 L / min

Test time: calculated according to the shell surface area of the tested sample, 1 min per square meter (excluding the installation area), at least 5 min

(4)IPx 4

Method name: splash test

Test method:

a. Pendulum splash test

Test equipment and sample placement: the same as paragraph a of IPX 3 above;

Test conditions: except for the following conditions, they are the same as paragraph a of IPX 3 above; The water spray area is the water spray from the water spray hole in the 90 ° arc section on both sides of the midpoint of the pendulum tube to the sample. Place the sample at the semicircle center of the pendulum tube. The pendulum tube swings 180 ° on both sides of the vertical line, with a total of about 360 °. Each swing (2 × 360 °) about 12s

Test time: the same as paragraph a of IPX 3 above (i.e. 10 min).

b. Sprinkler splash test

Test equipment and sample placement: the same as paragraph B of IPX 3 above;

Test conditions: remove the baffle with counterweight installed on the equipment, and the rest are the same as item B of IPX 3 above;

Test time: the same as item B of IPX 3 above, that is, 1 min per square meter (excluding installation area) and at least 5 min based on the surface area of the tested sample shell

(5)IPx 5

Method name: water spray test

Test equipment: the inner diameter of the spray port of the nozzle is 6. 3mm

Test conditions: make the distance between the test sample and the water spray port be 2. 5m ~ 3M, and the water flow is 12. 5 L/min ( 750 L/h )

Test time: 1 min per square meter (excluding installation area) and at least 3 min based on the shell surface area of the tested sample

(6)IPx 6

Method name: strong water spray test;

Test equipment: the inner diameter of the spray port of the nozzle is 12. 5 mm

Test conditions: make the distance between the test sample and the water spray port be 2. 5m ~ 3M, water flow of 100 l/min (6000 l/h)

Test time: 1 min per square meter (excluding installation area) and at least 3 min based on the shell surface area of the tested sample

(7)IPx 7

Method name: short time immersion test

Test equipment and test conditions: immersion tank. The size shall be such that the distance from the bottom of the sample to the water surface shall be at least 1m after the sample is put into the soaking tank. The distance from the top of the sample to the water surface shall be at least 0. 15m

Test time: 30 min

(8)IPx 8

Method name: continuous diving test;

Test equipment, test conditions and test time: it shall be agreed by the supplier and the buyer, and its severity shall be higher than IPX 7.

Note: in addition, many outdoor electronic products also emphasize the floating ability.