Welding procedure qualification PQR

PQR is the English abbreviation of welding procedure qualification record, so it is sometimes written as WPQR, which is generally translated as "welding procedure qualification report". PQR refers to the record of actual welding parameters and the results of nondestructive testing and mechanical property test when welding qualification test pieces. Since it was introduced from abroad in the 1970s, it has been an indispensable working procedure in the manufacturing, installation and repair of pressure vessels and pressure pipelines, and is the basis for evaluating the welding technology level (qualification) of manufacturing, installation and repair units. Because of its scientific, reasonable and strict evaluation process, it is also used in steel structure, tank manufacturing and installation industries. Although the names are somewhat different (some are called welding process test), the methods and requirements are basically the same.

In the manufacture of pressure pipes, ships and other products, two forms of welding documents are often encountered, namely, welding procedure document (WPS) and welding procedure qualification report (PQR). Welding manufacturing specifications at home and abroad require enterprises to conduct welding process evaluation to verify the basic ability of enterprises to weld joints that meet the standard (minimum threshold index). Generally, the welding procedure qualification is prepared by the technical department of the enterprise. According to the product requirements, it is implemented in accordance with relevant standards such as ASME section IX in the United States, European EN 288-3 and nb/t47014-2011 in China. According to the standard, welding procedure qualification test shall be carried out for each change of important parameters, such as welding method, base metal category (group number), preheating temperature, heat treatment temperature and welding heat input beyond the specified range. Because there are many process parameters that affect the mechanical properties of welded joints, many enterprises have accumulated a large number of welding procedure qualification reports.

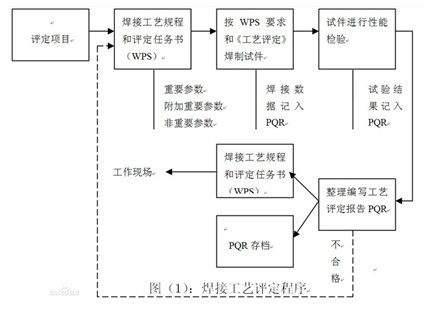

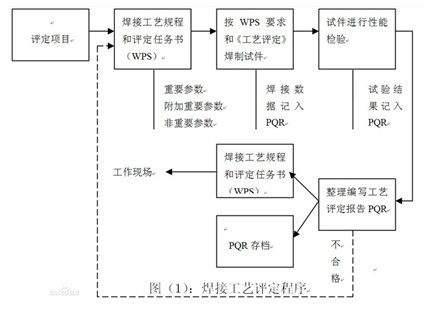

A complete welding procedure qualification procedure can generally be divided into five steps: putting forward the procedure qualification items; Prepare process qualification assignment and welding specification; Conduct process qualification test; Prepare process evaluation report; Prepare welding procedures to guide production. The procedure is shown in the following figure:

PQR is a result record in the later stage of welding procedure qualification, which is finally signed and approved by the technical department of the company. PRQ is obtained through welding procedure qualification tests. Its purpose is to:

A inspect whether the proposed welding process (pWPS) is operable and reasonable;

B. whether the selection of welding materials is correct and whether the welding process parameters are appropriate;

C. prove that the equipment, personnel and other technical conditions of the factory are in good condition, have the ability to engage in the specified welding process, and can obtain the welding quality that meets the standard requirements.